Precision Engineering

Built for Excellence

Delivering high-accuracy components for Robotics, Medical, Automation, Packaging & More.

About Us

Welcome to Amrita Engineering Works

AMRITA ENGINEERING WORKS is an ISO 9001:2015, 14001:2015 & 45001:2018 certified company specializing in high-precision machining components. We serve key industries like Medical Equipment, Robotics, Automation, Packaging, Electronics and more.

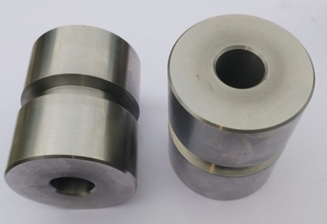

We manufacture tailor-made components including Rollers, Shafts, Sprockets, Brass & Copper Components, Aluminium Plates, SS Channels, Delrin/PVC/Nylon parts and sub-assemblies using materials like MS, SS (All grades), Brass, Copper, Aluminium, etc.

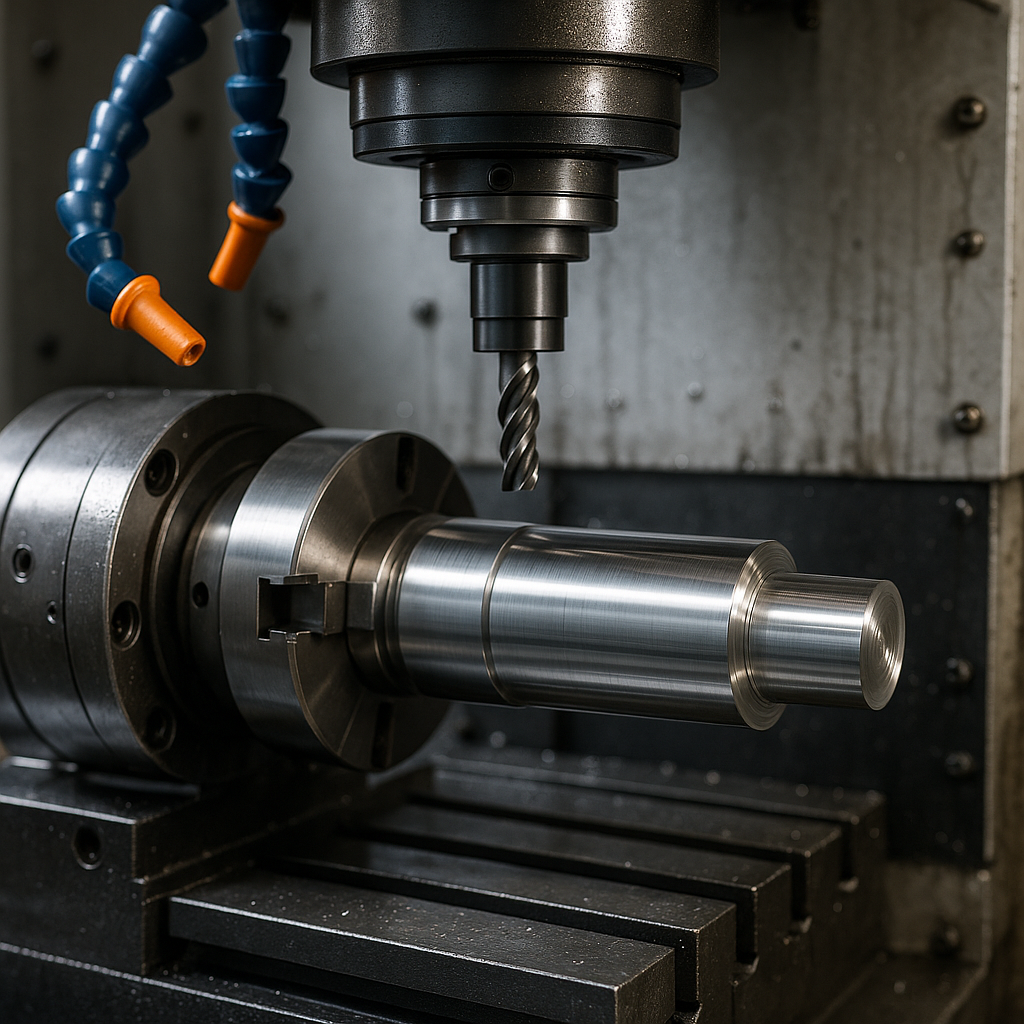

Equipped with state-of-the-art machines such as VMCs, CNC Turning Machines, Milling Machines, Surface Grinders, Lathes, and supported by a skilled technical team, we ensure best-in-class quality, cost efficiency, and timely delivery.

15

Years of

Experience

500+

Precision

Components Delivered

Our Founder

A.L. Maurya

Founder & Managing Director

Mr. A.L. Maurya, an Engineering Graduate specialized in manufacturing, established Amrita Engineering Works in the year 2010. With over 15 years of industry experience in the automotive sector, he brings deep knowledge of engineering, operations, and quality systems.

His vision is to deliver precision machining solutions with the highest standards of quality and reliability, empowering Indian manufacturing across industries.

Under his leadership, the company has grown into a trusted partner for OEMs and industrial clients across sectors like robotics, automation, and medical equipment.

Our Team

Engineering Expertise

Meet our dedicated team of skilled engineers and machine operators who ensure top-quality precision machining on every component delivered.

B.Tech Engineer

Production & QC SpecialistDiploma Engineer

Machine Programming & InspectionSenior Machine Operator

15+ Years in Turning & MillingQA Inspector

Skilled in Vernier, Bore, TRG/TPG GaugesInfrastructure

Advanced Manufacturing Capabilities

Our facility, spread across 500 sq. yards in Rajender Nagar Industrial Area, Ghaziabad, is a state-of-the-art precision machining setup designed for scalable, high-mix production. We operate with 24x7 power backup and a robust supply chain network ensuring zero downtime.

The shopfloor is equipped with a hybrid suite of CNC, VMC, turning, and high-precision inspection units. Some of our flagship machines include:

- Hailokesh VML 1200: Vertical Machining Center with 1200 mm X-axis travel — ideal for large plate and block milling.

- BAGSON 7464: Surface grinding system with micron-level flatness control, suitable for toolroom & fixture applications.

- CYM W60: Semi-automatic drilling and tapping station — compact yet powerful for batch operations.

- TL 250: CNC turning center with 250 mm chuck, excellent for high-volume shaft and threaded part production.

Additionally, the facility houses Pacmill 900x400x400 milling machines (5 Nos), CNC Turning Ø250x500 capacity machines, and Ramanna 460x260 Surface Grinder for intricate finishing jobs.

Quality Assurance

Precision Inspection & Quality Control

We follow a stringent, process-driven quality management system in alignment with ISO 9001:2015 standards. Our quality lab is equipped with calibrated instruments and gauges to verify tolerance, hardness, and surface finish parameters.

Major Inspection Equipment Includes:

- Material Hardness Tester

- Digital Vernier Calipers (0.001 mm accuracy)

- Bore Gauges (10–160 mm range)

- Slip Gauge Blocks

- TPG / TRG (Thread Plug & Ring Gauges)

- Outside Micrometers (0–175 mm)

- Surface Plate with Coating Thickness Gauge

Every outgoing component is validated through an Inspection Report which includes Material Test Certificate (MTC), Coating Reports, and Dimensional Inspection Sheets, based on drawing specification and customer requirements.

Manufacturing Workflow

Streamlined Production Cycle

Our production cycle is structured to minimize lead times while maximizing repeatability and dimensional control. The flow ensures full traceability and multi-level inspection across all stages:

- Purchase Order Confirmation: Job order initiated with customer-approved technical drawings and raw material specification.

- Raw Material Sourcing: Materials such as MS, SS, Aluminium, Brass, PVC, Delrin, and UHMW are pulled from our in-house inventory.

- Component Manufacturing: CNC/VMC operations such as turning, slotting, tapping, milling, and surface grinding using TL 250, Hailokesh VML 1200, and Pacmill machines.

- In-Process Inspection: Operator and QA checkpoints with GO/NO-GO gauges, slip gauges, and bore testing tools.

- Deburring & Polishing: Surface treatment for sharp edge removal, uniformity, and cosmetic finish.

- Final Quality Inspection: Comprehensive validation against drawing using micrometers, TPG, TRG, and hardness gauges.

- Packing & Dispatch: Bubble-wrapped, oil-coated parts with inspection reports and documents ready for dispatch.

With this streamlined workflow, we ensure zero-defect deliveries and maintain customer satisfaction through consistency and compliance.